The world of electronics is evolving at an astonishing pace, and the demand for intricate and reliable systems is higher than ever before. In this article, we delve into the realm of PCB (Printed Circuit Board) Box Build Assembly services, exploring the significance, scope, and valuable role they play in bringing complex electronic systems to life.

1. The Significance of PCB Box Build Assembly Services

PCB Box Build Assembly services encompass the integration and assembly of various electronic components into a finalized enclosure or “box.” These services are crucial in transforming a collection of individual components into a fully functional electronic system. Whether it’s a complex industrial automation system, a cutting-edge medical device, or a sophisticated aerospace control unit, PCB Box Build Assembly is the key to making it all work seamlessly.

2. A Wide Scope of Applications

The applications of PCB Box Build Assembly services are incredibly diverse and include:

- Industrial Automation: Complex machinery and robotic systems often require intricate PCB assembly to control and monitor various processes.

- Medical Devices: Life-saving medical equipment, such as patient monitors and diagnostic devices, rely on precise PCB Box Build Assembly for accuracy and reliability.

- Telecommunications: High-speed data networks and communication systems depend on robust electronics assembly for uninterrupted connectivity.

- Consumer Electronics: From smart appliances to entertainment systems, PCB Box Build Assembly is at the heart of modern gadgets.

- Aerospace and Defense: In mission-critical environments, such as aircraft and military equipment, precision and reliability are non-negotiable.

3. Key Components of PCB Box Build Assembly

- Electronic Components: The assembly process involves the integration of various electronic components, such as PCBs, connectors, sensors, microcontrollers, and more.

- Enclosures: The choice of enclosure is crucial, as it determines the physical protection and environmental resilience of the assembled system.

- Wiring and Cabling: The meticulous routing of wires and cables is essential to ensure proper connectivity and prevent interference.

- Testing and Quality Control: Rigorous testing and quality checks are integral to PCB Box Build Assembly to ensure that the final product meets specifications and standards.

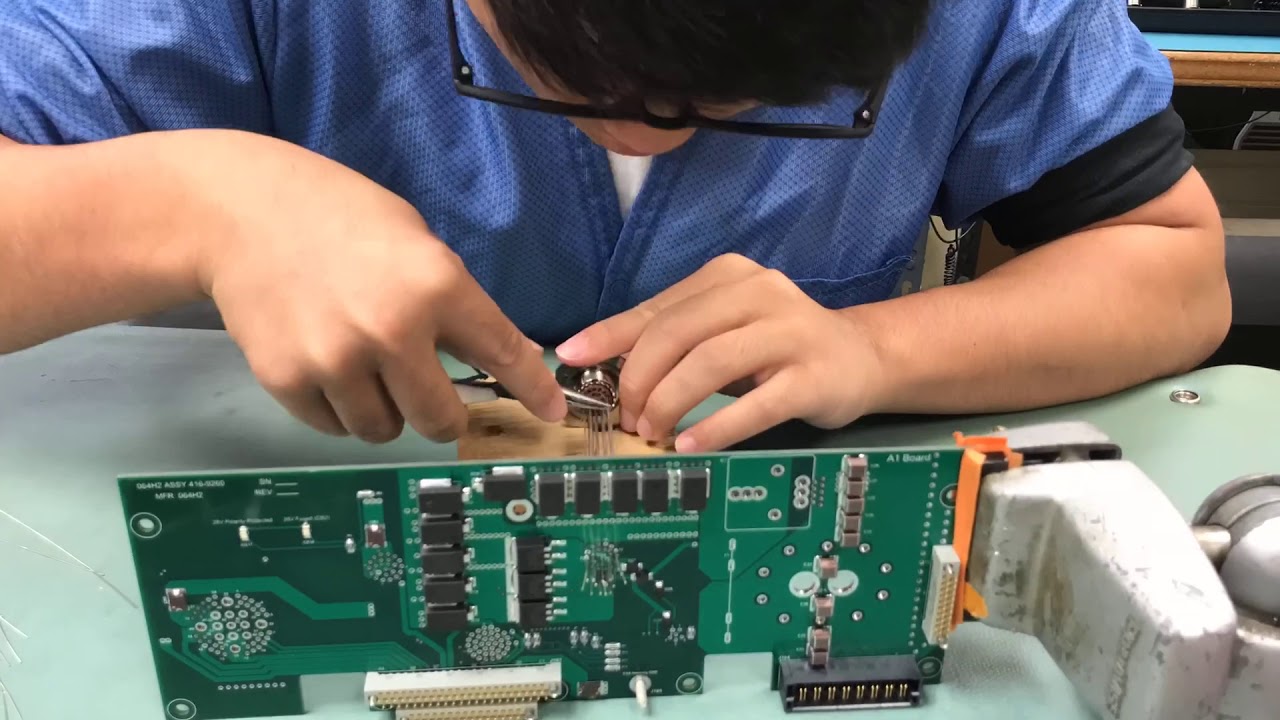

4. Precision and Expertise

PCB Box Build Assembly demands a high level of precision and expertise. Every component must be meticulously placed, and connections must be secure and reliable. This process requires skilled technicians and advanced equipment.

5. Customization and Scalability

One of the advantages of PCB Box Build Assembly services is their ability to cater to specific needs. Whether you require a one-of-a-kind prototype or a large-scale production run, these services can be tailored to your requirements.

6. Quality Assurance

Quality is paramount in PCB Box Build Assembly Anzer. Components must function flawlessly in real-world conditions. Robust quality assurance procedures, including functional testing, ensure that the final product performs as expected.

Conclusion

In conclusion, PCB Box Build Assembly services are the backbone of modern electronics manufacturing. They bring together individual components to create fully functional electronic systems that power our industries, healthcare, communication, and daily lives. As technology continues to advance, the role of PCB Box Build Assembly will remain indispensable in shaping our increasingly interconnected and sophisticated world.